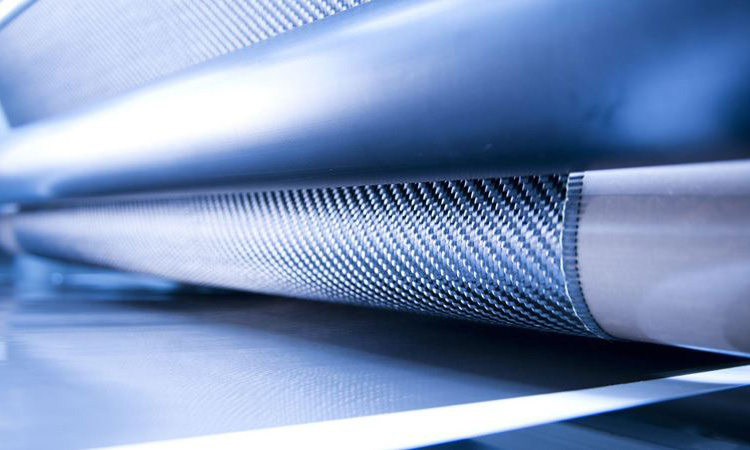

Advanced composite materials (ACMs) or composites with advanced polymer matrix contain fibers with high strength and rigidity compared to other materials. These materials combine with relatively weaker matrices. The reason for naming these materials as Advanced Composite Materials (ACM) in comparison with other composite materials such as reinforced concrete or even concrete itself is specified. These fibers with high strength and low density occupy a large part of the volume.

Advanced composites have desirable physical and chemical properties, including low weight with high stiffness (elasticity) and high strength along the reinforcing fiber, subsequent stability, temperature and chemical resistance, flexible performance and relatively easy processing. Advanced composites are being replaced by metal parts in many applications, especially in the aerospace industry.

Composites are classified according to their matrix phase. These classifications include polymer matrix composites (PMCs), ceramic matrix composites (CMCs), and metal matrix composites (MMCs). Also, materials in this classification are often called “advanced” if they include properties such as high strength (axial, longitudinal) and high hardness (axial, longitudinal), low weight, corrosion resistance, and in some cases specific electrical properties.

Advanced composite materials have wide and proven applications in the aerospace, aerospace and sports equipment industries. ACMs in particular are very attractive to aircraft parts and aerospace structures. ACMs have been developed for advanced space transport design, protective armor for US Army and Federal Aviation Administration air transport, and high temperature shaft for Comanche helicopter. In addition, ACMs have a long history in the civil and military aviation industries. However, this technology is relatively new and is not officially offered in secondary or undergraduate education. Advanced composite manufacturing technology is constantly evolving.