Expanded polypropylene, or EPP, is a bubble or layer of polypropylene that has a good compressive strength due to its low stiffness and allows it to return to its original state after application, and is widely used in the aerospace and control industries. Radio is used, which is due to the ability to absorb pressure.

The name of this product is polypropylene (PP) and its chemical formula is [CH2-CH (CH3)] n. Polypropylene is one of the most widely used and essential polymers in the world and the largest consumer of propylene.

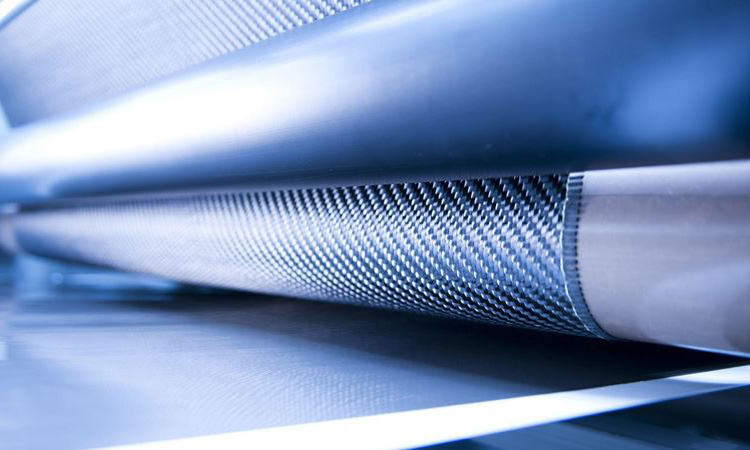

Polypropylene Polypropylene is polymerized at relatively mild temperatures and pressures in the presence of the famous Ziegler-Nata catalyst. The presence of this catalyst forms an isotactic polymer that is able to crystallize up to about 90%.

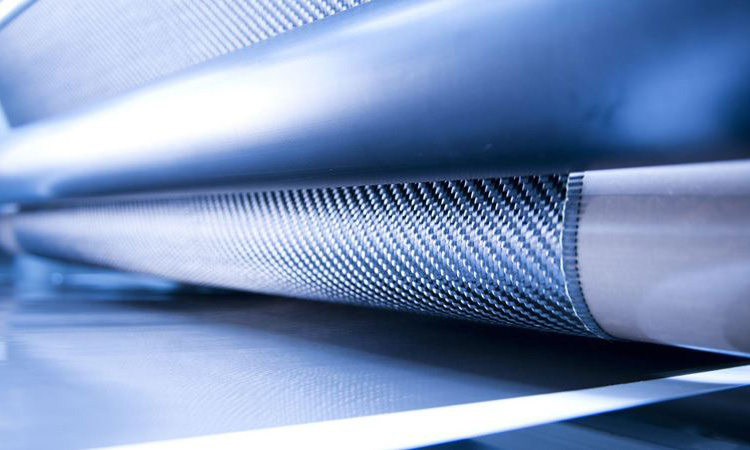

Polypropylene is a thermoplastic polymer that is used in a wide range of applications including film and sheet, blow molding, injection molding, food packaging, textiles, laboratory and medical equipment, pipes, industrial and construction applications, and automotive components. In addition, the polymer produced from the propylene monoprote is typically resistant to chemical solvents, bases and acids. The characteristic code of this polymer is.

The propylene molecule has an asymmetric chemical structure, so its polymerization process can lead to three types of sequences in the resulting polymer structure. Due to the effects of spatial inhibition of methyl groups, the tail-to-tail sequence has a higher structural order than other types.

Polypropylene has three different spatial configurations: isotactic (iPP), syndiotactic (sPP) and atactic (aPP). In the isotactic type, methyl groups are on one side of the plate passing through the main chain. In the syndiotactic type, methyl groups are placed one by one on both sides of the plate passing through the chain. There is no special order in the type of ataktik.

A Ziegler-Nata catalyst is able to limit the placement of the solids in a special arrangement and only lets the solids be added to the polymer chain in the right direction. Most common polypropylenes produced using titanium chloride (Ticl4) catalysts have a high percentage of isotactic polypropylene. Because the methyl groups are on one side, some molecules tend to spiral, coming together one at a time to form the usual polypropylene resistor.

The commercialized iPP has a variety of properties that have led to its widespread use, especially in the plastics and fiber industry. One of the most important properties of this material compared to polymers such as polyamides is its lack of moisture absorption, which has made it a suitable option for many applications. The properties of this material can be improved by making some subsequent modifications. The most important improvements that are currently being made are the control of the degradation process, networking, operationalization and branching. The structure of the polypropylene molecule is linear due to the nature of Ziegler-Nata catalysts, which leads to low melt strength. Low melt strength limits the application of this polymer in processes such as blow molding and thermoforming.

Polypropylene is one of the most widely used polymers, with global production reaching about 35.8 million tonnes in 2003.

Annual growth in global demand for polypropylene between 2003 and 2008 is estimated at 6.7 percent. The highest demand in the industries is the production of fiber-reinforced equipment, filament yarn production, plastic injection and pneumatic injection.

Compared to other polymers, polypropylene has distinct and prominent characteristics, which are:

Relatively cheap price of propylene monolayers compared to other monomers of polymers

• Low price of PP compared to other polymers

• Specific weight and light PP

• Flexibility and wide range of PP production with variable physical and chemical properties

• Increase new applications and improve the properties of new product lines

• Increasing the use of PP in medical devices and equipment and developing PP applications for a specific category

• Increase the consumption of PP as an alloy with other polymers

• Replacement with polymers such as PS, PE, etc.